Aggregate Mining

Aggregate mining is an inherently destructive act, one that involves removing non-renewable resources like limestone, sand, and gravel, from deep within the earth. This comes at a heavy cost to the environment and local communities.

Aggregate mining is an inherently destructive act, one that involves removing non-renewable resources like limestone, sand, and gravel, from deep within the earth. This comes at a heavy cost to the environment and local communities.

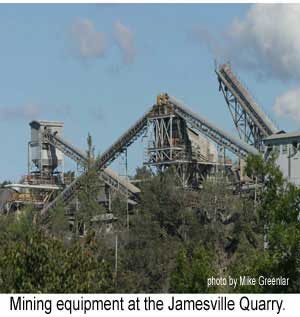

Open-pit mining, the type of mining used at the Jamesville Quarry, is exactly what it sounds like — a gaping pit carved out of the land. In the case of the Jamesville Quarry, the land formerly consisted of pristine lakes, gorges, ice caves, and other unique geological features. Now the land is little more than a 1,174 acre trench. Another 1,064 acres is considered part of the quarry.

Hanson Aggregates North America

Hanson Aggregates North America (HANA) is the North American subsidiary of Hanson PLC, a multi-national corporation headquartered in London. A billion-dollar company and the third largest producer of aggregate in the United States, HANA has 329 active mines, ready-mix concrete operations, asphalt, and other operations in 16 states. Hanson employs over 5,100 people, and in 2004 received $33.6 million in federal highway funding.

In New York, HANA operates 13 limestone mines, 16 sand and gravel mines, and 1 dolostone (a stone like limestone that is used in construction) mine.

In January 1992, HANA received the 1,800 acre Jamesville Quarry when it acquired the General Crushed Stone Co. Today, HANA mines 2.2 million tons of stone per year for use in construction aggregate from the Jamesville Quarry.

Jamesville Quarry

[lightbox link=”http://www.onondaganation.org/wp-content/uploads/2014/02/jamesquarry2.jpg” thumb=”http://www.onondaganation.org/wp-content/uploads/2014/02/jamesquarry2-300×209.jpg” width=”300″ align=”right” title=”jamesquarry2″ frame=”true” icon=”image”]The Jamesville Quarry occupies 2,238 acres of the Onondaga Escarpment — a 550 million year old limestone ledge that runs west to Butternut Creek valley, then through Rock Cut into and up Onondaga Creek valley. Operations at the quarry began in the 1850s, and were substantially expanded in 1909 to supply the Solvay Process soda-ash manufacturing operation. When the Solvay operation closed in 1986, it left behind 70 million tons of waste rock, now a principal source of crushed stone and aggregate.

Mining and New York State

Mining laws in New York State are designed primarily to promote the mining industry, not to protect environmental quality. The Department of Environmental Conservation is responsible for implementing the mining laws, but the mining programs are chronically under funded and inadequately staffed.

Local laws do not afford any protection either. New York’s mining law expressly limits local regulation of mining to such a degree that many municipalities, fearing law suits, don’t regulate at all. Reclamation of aggregate — or restoring the land to it’s original state — mines is difficult. Even when attempts to reclaim a mine are made, they often fail to restore the property to an economically viable piece of real estate.